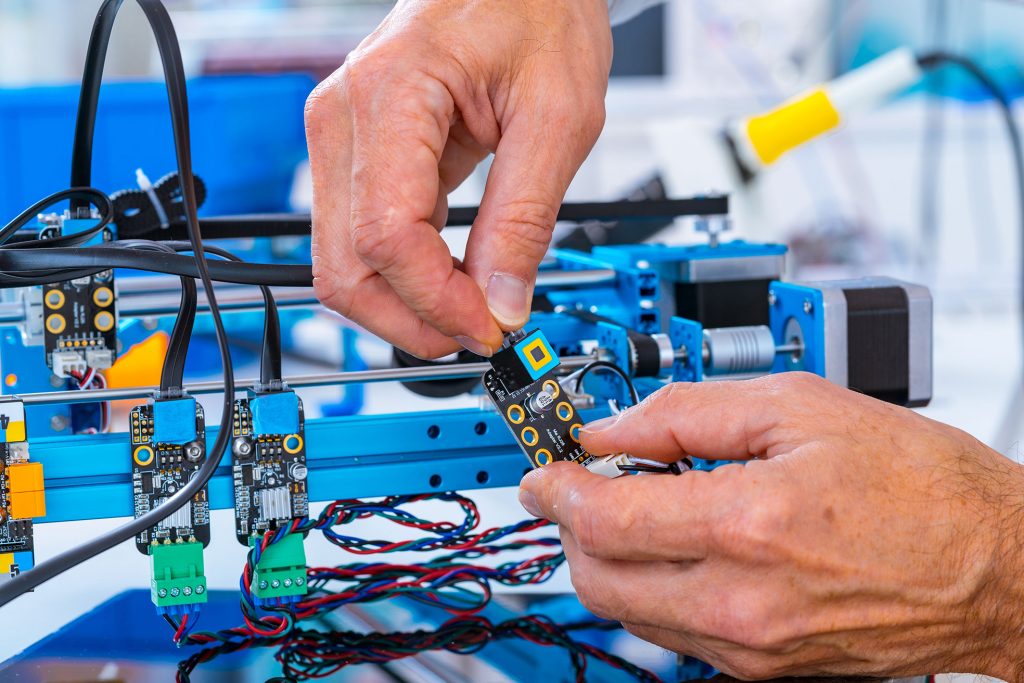

In electronics manufacturing, the quality of soldering can make or break the reliability and functionality of electro-mechanical assemblies. As devices become more compact and demands on their performance increase, traditional soldering techniques often fall short. This has led to the development and adoption of advanced soldering techniques that ensure stronger, more reliable connections even in complex systems. These advanced techniques contribute to the robustness of electro-mechanical assemblies in several ways.

Fundamentals of Soldering in Electro-Mechanical Assembly

Soldering is a process that joins two or more electronic components together by melting and putting a filler metal (solder) into the joint. The solder usually has a lower melting point than the adjoining metal. Commonly used methods in an electro-mechanical assembly include wave soldering, manual soldering, and reflow soldering. Each method presents its own set of challenges, such as ensuring even heat distribution, preventing component damage due to overheating, and achieving consistent solder quality across numerous joints.

The limitations of conventional soldering techniques for modern electro-mechanical assembly applications have paved the way for more sophisticated approaches:

● Laser Soldering: This technique uses a focused laser beam as the heat source, providing high precision and control. Ideal for delicate components, laser soldering minimizes the risk of thermal damage and allows for pinpoint accuracy. It is also suitable for densely packed PCBs where traditional soldering irons cannot reach without causing damage.

● Induction Soldering: This method generates heat using electromagnetic induction. It offers rapid and uniform heating and is highly energy efficient. Induction soldering is particularly effective for joining larger components that require consistent heat application over a wider area to form a robust joint.

● Selective Soldering: As an automated alternative to hand soldering, selective soldering machines target specific areas on a PCB, avoiding heat exposure to the entire board. This method combines the efficiency of wave soldering with the precision of manual soldering, making it ideal for complex boards with high-density component layouts. To avoid the costs of investing in these machines, it’s essential to consider the services of a reliable electronic assembly manufacturer for selective soldering.

● Reflow Soldering: Widely used in the assembly of SMDs (Surface Mount Devices), reflow soldering involves applying solder paste to the board, placing components on top, and then passing the assembly through a controlled heat cycle. This melts the solder and solidifies it, forming strong electrical and mechanical bonds. Reflow soldering is crucial for achieving high throughput in PCB assembly with excellent joint quality.

Materials and Tools for Advanced Soldering

The success of advanced soldering techniques heavily relies on the quality of materials and tools used in the process. Modern, high-performance solder materials, including lead-free solders, meet stringent environmental standards and possess enhanced mechanical properties necessary for enduring the rigors of advanced applications. Alongside these materials, sophisticated soldering equipment plays a pivotal role. High-precision soldering irons, state-of-the-art reflow ovens, and wave machines enable precise and efficient soldering. Thermal profilers and optical inspection systems ensure that each joint meets the highest quality standards. For companies lacking these capabilities, outsourcing to an electronic assembly manufacturer equipped with these advanced tools can be a viable option, ensuring access to top tier soldering without the overhead of direct investment.

Various Applications of Advanced Soldering Techniques

Advanced soldering techniques are utilized across a variety of sectors due to their enhanced precision and reliability:

● Aerospace and Defense: These sectors require extremely reliable solder joints for mission-critical systems where failure is not an option. Laser and induction soldering are often employed here for their precision and robustness.

● Consumer Electronics: As devices such as smartphones and tablets become thinner and more complex, advanced soldering helps accommodate the small-scale and high-density integration of components.

● Automotive Industry: With the increasing electronic integration in vehicles, advanced soldering ensures the durability and reliability required for automotive components, which must withstand harsh environments and vibrations.

● Medical Devices: Advanced soldering is critical in medical devices where reliable and precise connections are crucial for device functionality and patient safety.

Advanced soldering techniques are revolutionizing electro-mechanical assembly, enabling the production of highly reliable and robust devices. As technology continues to advance, these soldering methods will become even more critical in meeting the demands of modern electronic design and manufacturing. Embracing these advanced techniques is essential for manufacturers aiming to stay competitive in a rapidly evolving industry.